In today’s complex business landscape, effective inventory management is crucial for success. Inventory management involves a multitude of processes, and at the heart of it all lies the Stock Keeping Unit (SKU). SKUs are unique identifiers assigned to each distinct product or service a business offers. They are fundamental for tracking inventory levels, analyzing sales data, and optimizing warehouse operations. This comprehensive guide will delve into the importance of SKUs in inventory management, outlining the numerous benefits they offer and providing practical insights into their effective implementation.

Understanding the importance of SKUs is the first step toward streamlined inventory control and improved operational efficiency. From accurate inventory tracking and reduced stockouts to data-driven decision-making and enhanced customer satisfaction, SKUs play a pivotal role in driving business growth and profitability. Whether you’re a small startup or a large enterprise, mastering the use of SKUs in inventory management is essential for achieving sustainable success. This guide will equip you with the knowledge and strategies you need to leverage the power of SKUs to their fullest potential.

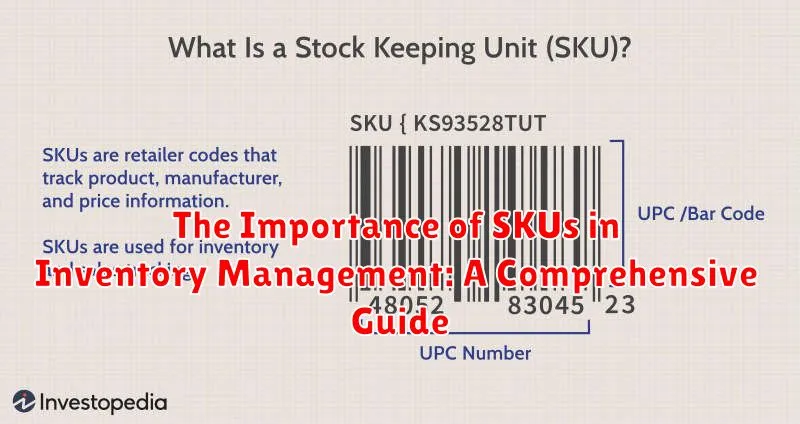

What is a SKU?

A Stock Keeping Unit (SKU) is a unique alphanumeric code used to identify and track inventory. It’s a scannable bar code, often affixed to products, that allows businesses to manage, track, and organize products in their warehouses or retail stores. Each distinct product variation necessitates a separate SKU. This includes differences in size, color, style, and other attributes.

Think of a SKU as a product’s unique fingerprint within your business. This identification code allows for the seamless differentiation of products within a complex inventory system. SKUs provide the granular level of detail required for precise inventory management, allowing businesses to monitor stock levels, analyze sales data, and ultimately, optimize profitability.

Why SKUs Matter in Inventory Management

SKUs are essential for efficient and accurate inventory management. They provide a unique identifier for each product, enabling businesses to track stock levels, manage orders, and analyze sales data effectively. Without SKUs, managing a diverse inventory becomes a chaotic and error-prone process.

Improved Inventory Accuracy: Using SKUs eliminates ambiguity when dealing with similar products. This precision leads to better inventory counts and reduces the risk of stockouts or overstocking.

Streamlined Operations: SKUs simplify warehouse operations. Staff can quickly locate and retrieve items using the SKU, speeding up order fulfillment and other processes.

Data-Driven Decisions: By tracking SKUs, businesses gather valuable data on product performance. This information is crucial for making informed decisions regarding pricing, purchasing, and marketing strategies.

Enhanced Customer Satisfaction: Efficient inventory management, powered by SKUs, ensures that customers receive the correct products promptly. This accuracy contributes significantly to customer satisfaction and loyalty.

Creating Effective SKU Numbers

Creating effective SKUs is crucial for efficient inventory management. A well-defined SKU architecture provides clarity and streamlines operations. Here’s a breakdown of key considerations:

Key Considerations for SKU Creation

Uniqueness: Each SKU must be unique to a specific product variant. This avoids confusion and ensures accurate tracking.

Simplicity: Keep SKUs concise and easy to understand. Avoid overly complex numbering systems that can be difficult to manage.

Consistency: Maintain a consistent structure across all SKUs. This facilitates easier searching and sorting.

Logical Structure: Incorporate product attributes into the SKU structure. This might include product category, size, color, or other defining characteristics.

Example SKU Structure

Consider a t-shirt with the following attributes: Category (TSH), Color (BLU), Size (L). A possible SKU could be TSH-BLU-L.

Avoid Common Mistakes

Avoid using special characters or spaces in SKUs. Stick to alphanumeric characters to ensure compatibility across systems.

Don’t embed meaningful information that might change, such as price or supplier, within the SKU.

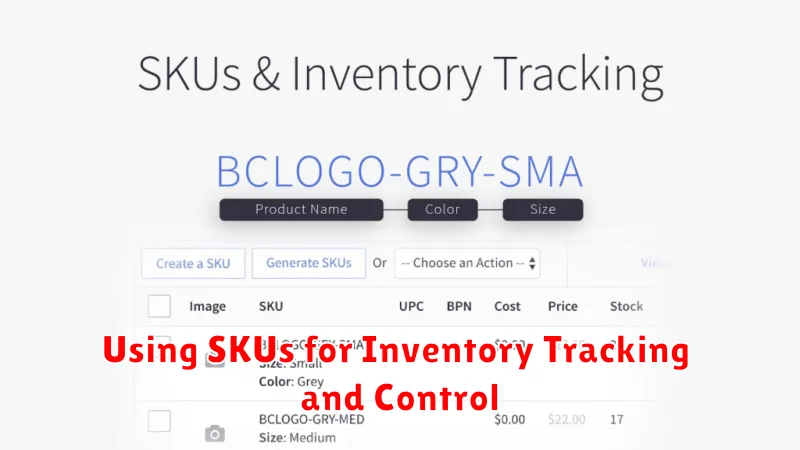

Using SKUs for Inventory Tracking and Control

Effective inventory tracking hinges on accurate identification. SKUs provide the granular detail necessary to monitor individual items throughout their lifecycle within your warehouse or store. This precise identification allows for real-time visibility into stock levels.

By associating quantities with specific SKUs, businesses can pinpoint the exact location and quantity of each product variation. This precision eliminates the ambiguity associated with generalized product categories, enabling more efficient stocktaking and reducing the risk of inventory discrepancies.

Automated inventory management systems utilize SKUs to streamline processes. When a sale occurs, the system automatically decrements the corresponding SKU’s quantity, providing up-to-the-minute stock information. This automation minimizes manual data entry, reduces human error, and facilitates more accurate demand forecasting.

Moreover, SKUs are essential for managing product movement within a warehouse. By tracking SKUs during receiving, putaway, picking, and shipping, businesses can optimize warehouse layout and improve operational efficiency. This detailed tracking also strengthens inventory control by providing an audit trail for each item, reducing instances of loss or theft.

Leveraging SKUs for Sales Analysis and Forecasting

SKUs provide the granular data necessary for effective sales analysis and accurate forecasting. By tracking sales data at the SKU level, businesses gain valuable insights into product performance, customer preferences, and overall market trends.

Analyzing sales data by SKU allows businesses to identify top-performing products, as well as slow-moving or obsolete items. This information is crucial for making informed decisions about inventory management, such as adjusting stock levels, optimizing pricing strategies, and discontinuing underperforming products.

Furthermore, SKU-level sales data enables businesses to forecast future demand. By analyzing historical sales patterns for each SKU, businesses can predict future sales volumes and make proactive decisions about inventory replenishment. This helps to avoid stockouts and ensures that businesses have the right products available at the right time.

Sophisticated inventory management systems can leverage SKU data to generate automated reports and data visualizations that provide a clear overview of sales performance. This enables businesses to quickly identify trends, make data-driven decisions, and improve overall profitability.

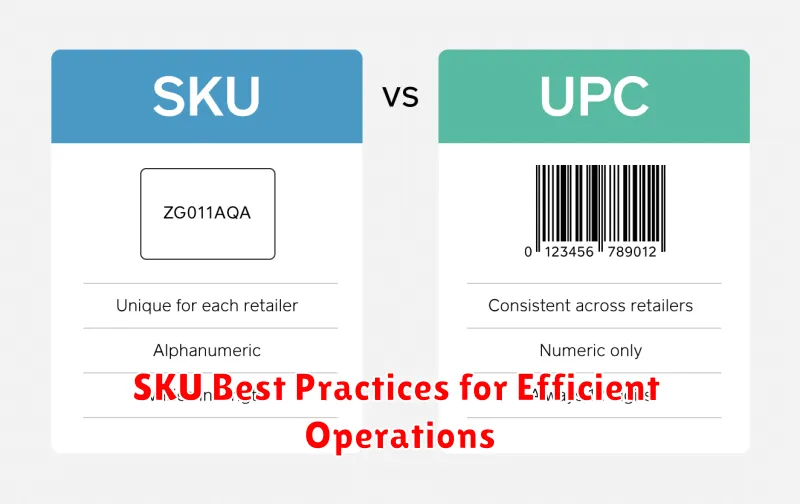

SKU Best Practices for Efficient Operations

Implementing effective SKU practices is crucial for streamlined inventory management. A well-structured SKU architecture enables accurate tracking, efficient retrieval, and optimized warehouse organization.

Start by establishing a consistent format. Define the length, characters used (alphanumeric, numeric), and the meaning of each segment within the SKU. This ensures uniformity across all products and simplifies data analysis.

Logical sequencing is another key practice. Group related products together by incorporating product attributes like category, size, or color within the SKU structure. This allows for easier identification and retrieval within the warehouse.

Avoid using special characters or spaces in your SKUs. These can cause issues with certain systems and databases. Stick to alphanumeric characters for optimal compatibility.

Finally, regularly review and update your SKU system. As your product catalog evolves, ensure your SKUs remain relevant and accurately reflect your inventory. This proactive approach prevents inconsistencies and maintains data integrity.

Common SKU Mistakes to Avoid

Creating and managing SKUs effectively is crucial for streamlined inventory operations. However, certain pitfalls can hinder their usefulness. Avoiding these common mistakes will ensure your SKUs contribute to efficient inventory management.

Using Meaningful Characters: Avoid using special characters or spaces in your SKUs. Stick to alphanumeric characters to ensure compatibility across different systems and prevent errors in data processing. Using characters like “/” or “@” can lead to confusion and technical difficulties.

Starting with a Zero: While tempting, refrain from starting your SKUs with a zero. Some systems may interpret this as an octal value, leading to misinterpretations. Starting with a letter or a non-zero digit is best practice.

Inconsistent Length: Maintain a consistent length for your SKUs. This aids in visual organization and database management. Decide on a fixed number of characters and apply it uniformly.

Overly Complex SKUs: Keep your SKUs concise and to the point. While incorporating product attributes is useful, overly long and complex SKUs can be cumbersome and inefficient.

Not Updating SKUs: As your products evolve or new variations are introduced, remember to update your SKUs accordingly. Failing to do so will lead to inaccuracies in your inventory data.

Integrating SKUs with Your E-commerce Platform

Seamless integration between your SKUs and e-commerce platform is crucial for accurate inventory tracking, streamlined order fulfillment, and a positive customer experience. Most platforms offer direct SKU integration within their product management systems.

When adding a product, your e-commerce platform will typically have a designated field for the SKU. Ensure this field is mandatory to prevent accidental omissions. The platform should automatically link this SKU with the product’s listing, inventory count, and order details.

Leveraging this integration, you can automate several key processes. For instance, when an order is placed, the platform can automatically decrement the corresponding SKU’s inventory count, preventing overselling. This automated inventory management reduces manual data entry and minimizes the risk of errors.

Furthermore, SKU integration facilitates efficient order fulfillment. Warehouse staff can easily locate products using the SKU, speeding up picking and packing processes. This contributes to faster shipping times and improved customer satisfaction.